BT8C is an embedded Bluetooth low energy (BLE) module that Tuya has developed. It consists of a highly integrated Bluetooth chip (TLSR8253) and several peripheral components, with an embedded Bluetooth network protocol stack and robust library functions.

BT8C also contains a low-power 32-bit multipoint control unit (MCU), BLE 5.0 component, 2.4 GHz radio component, 4 Mbits flash memory, 48 KB static random-access memory (SRAM), and three multiplexing I/O interfaces.

|Date|Change description|Version after change|

|20190723|Optimized the pin definition, Standardized the dimensional tolerances, Updated the temperature range, oven temperature, and working voltage settings, Added packing methods.|V2.0.0|

|20191012|Delete the diagram of architecture|V2.0.1|

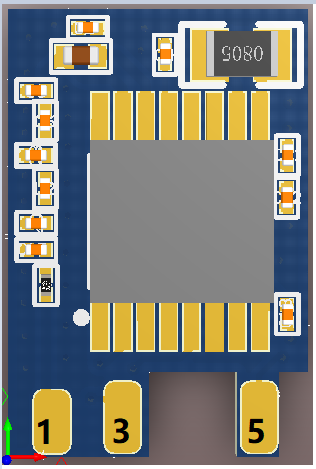

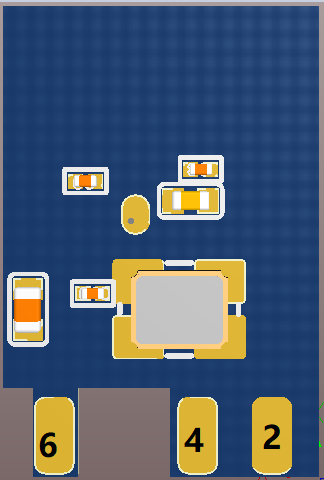

BT8C has six pins, for plug-in assembly.

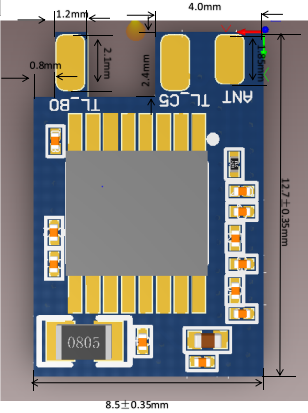

The BT8C dimensions (W x L x H) are 8.50±0.35mm ×12.7±0.35mm ×2.3±0.15mm. The PCB thickness is 1.0±0.1 mm. The BT8C pins show as below.

| Pin No. | Symbol | I/O type | Function |

|---|---|---|---|

| 1 | ANT | I/O | RF input and output port, which is connected to pin ANT on the IC |

| 2 | GND | P | Power supply reference ground pin |

| 3 | TL_C5 | I/O | Common I/O, which can be used as a PWM output of the LED drive and is connected to pin TL_C5 on the IC, inverting output with pin 5 |

| 4 | TL_B1 | I/O | Common I/O, which can be used as a PWM output of the LED drive or serial interface receiving pin (UART RX), which is connected to pin TL_B1 on the IC |

| 5 | TL_B0 | I/O | Common I/O, which can be used as a PWM output of the LED drive or serial interface transmission pin (UART TX), which is connected to pin TL_B0 on the IC |

| 6 | 3V3 | P | Power supply pin (3.3 V) |

Note:

- P indicates power supply pins, I/O indicates input/output pins, and AI indicates analog input pins.

- If you have special requirements for light colors controlled by PWM outputs, contact Tuya business personnel.

| Parameter | Description | Minimum Value | Maximum Value | Unit |

|---|---|---|---|---|

| Ts | Storage temperature | -65 | 150 | ℃ |

| VCC | Power supply voltage | -0.3 | 3.9 | V |

| Static electricity voltage (human body model) | TAMB-25℃ | - | 2 | kV |

| Static electricity voltage (machine model) | TAMB-25℃ | - | 0.5 | kV |

| Parameter | Description | Minimum Value | Typical Value | Maximum Value | Unit |

|---|---|---|---|---|---|

| Ta | Working temperature | -40 | - | 85 | ℃ |

| VCC | Working voltage | 2.7 | 3.3 | 3.6 | V |

| VIL | I/O low-level input | VSS | - | VCC*0.3 | V |

| VIH | I/O high-level input | VCC*0.7 | - | VCC | V |

| VOL | I/O low-level output | VSS | - | VCC*0.1 | V |

| VOH | I/O high-level output | VCC*0.9 | - | VCC | V |

| Symbol | Condition | Minimum Value(Typical) | Unit |

|---|---|---|---|

| Itx | Constant transmission, 10dBm output power | 22 | mA |

| Irx | Constant receiving | 6.3 | mA |

| IDC | Connected to a mesh network(Average) | 6.6 | mA |

| IDC | Connected to a mesh network(Peak) | 23 | mA |

| Ideepsleep1 | Deep sleep mode 1 (16 KB RAM is reserved.) | 1.2 | μA |

| Ideepsleep2 | Deep sleep mode 2 (No RAM is reserved.) | 0.4 | μA |

| Parameter | Description |

|---|---|

| Frequency band | 2.4GHz ISM band |

| Wireless standard | BLE 4.2/5.0 |

| Data transmission rate | 1Mbps, 2Mbps |

| Antenna type | External antenna |

| Parameter | Minimum Value | Typical Value | Maximum Value | Unit |

|---|---|---|---|---|

| Average RF output power | -22 | 10 | 10.5 | dBm |

| 20 dB modulation signal bandwidth (1 Mbit/s) | - | 2500 | - | KHz |

| 20 dB modulation signal bandwidth (2 Mbit/s) | - | 1400 | - | KHz |

| Parameter | Minimum Value | Typical Value | Maximum Value | Unit |

|---|---|---|---|---|

| RX sensitivity 1Mbps | - | -90 | - | dBm |

| RX sensitivity 2Mbps | - | -87 | - | dBm |

| Frequency offset 1Mbps | -250 | - | +300 | KHz |

| Frequency offset 2Mbps | -300 | - | +200 | KHz |

| Co-channel interference suppression | - | -10 | - | dB |

BT8C uses an external antenna.

To ensure optimal RF performance, it is recommended that the antenna be at least 15 mm away from other metal parts. If metal materials are wrapped around the antenna, the wireless signals will be reduced greatly, deteriorating the RF performance.

Note: The default dimensional tolerance is ±0.35 mm, and the tolerance for some measurements is ±0.1 mm. If a customer has other requirements, clearly specify them in the datasheet after communication.

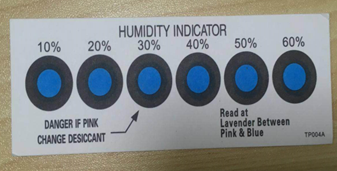

The stamp-hole module must be mounted by the SMT machine. After being unpacked, it must be soldered within 24 hours. Otherwise, it must be put into the drying cupboard where the RH is not greater than 10%, or it needs to be packaged under vacuum again and the exposure time needs to be recorded (the total exposure time cannot exceed 168 hours).

Storage conditions for a delivered module are as follows:

The module needs to be baked in the following cases:

Baking settings:

Important: If this batch of modules is not baked within 168 hours, do not use the wave soldering to solder them. Because these modules are 3-level moisture-sensitive components, they are very likely to get damp when exposed outside. In this case, if they are soldered at high temperatures, it may result in component failure or poor soldering.

In the whole production process, take electrostatic discharge (ESD) protective measures.

To guarantee the passing rate, it is recommended that you use the SPI and AOI to monitor the quality of solder paste printing and mounting.

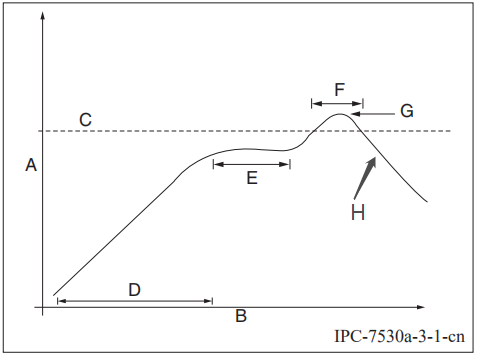

Perform mounting with the SMT based on the following reflow oven temperature curve. The highest temperature is 245°C. The reflow temperature curve is as below:

A: Temperature axis

B: Time axis

C: Liquidus temperature: 217 to 220°C

D: Ramp-up slope: 1 to 3°C/s

E: Duration of constant temperature: 60 to 120s; the range of constant temperature: 150 to 200°C

F: Duration above the liquidus: 50 to 70s

G: Peak temperature: 235 to 245°C

H: Ramp-down slope: 1 to 4°C/s

Note: The above curve is just an example of the solder paste SAC305. For more details about other solder pastes, please refer to Recommended oven temperature curve in the solder paste specifications.

| Product model | MOQ (pcs) | Packing method | Number of modules in each reel pack | Number of reel packs in each box |

|---|---|---|---|---|

| BT8C | 7200 | Carrier tape and reel packing | 1800 | 4 |

FCC Caution: Any changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate this device.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Note: This device has been tested and found to comply with the limits for a Class B digital device, according to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a residential installation. This device generates, uses, and can radiate radio frequency energy and, if not installed and used following the instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this device does cause harmful interference to radio or television reception, which can be determined by turning the device off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

Radiation Exposure Statement

This device complies with FCC radiation exposure limits set forth for an uncontrolled rolled environment. This device should be installed and operated with a minimum distance of 20cm between the radiator and your body.

Important Note

This radio module must not be installed to co-locate and operating simultaneously with other radios in the host system except following FCC multi-transmitter product procedures. Additional testing and device authorization may be required to operate simultaneously with other radios.

The availability of some specific channels and/or operational frequency bands are country dependent and are firmware programmed at the factory to match the intended destination. The firmware setting is not accessible by the end-user.

The host product manufacturer is responsible for compliance with any other FCC rules that apply to the host not covered by the modular transmitter grant of certification. The final host product still requires Part 15 Subpart B compliance testing with the modular transmitter installed.

The end-user manual shall include all required regulatory information/warnings as shown in this manual, including “This product must be installed and operated with a minimum distance of 20 cm between the radiator and user body”.

This device has got an FCC ID: 2ANDL-BT8C. The end product must be labeled in a visible area with the following: “Contains Transmitter Module FCC ID: 2ANDL-BT8C”.

This device is intended only for OEM integrators under the following conditions:

The antenna must be installed such that 20cm is maintained between the antenna and users, and the transmitter module may not be co-located with any other transmitter or antenna.

As long as the 2 conditions above are met, further transmitter tests will not be required. However, the OEM integrator is still responsible for testing their end-product for any additional compliance requirements required with this module installed.

Declaration of Conformity European Notice

Hereby, Hangzhou Tuya Information Technology Co., Ltd declares that this module product is in compliance with essential requirements and other relevant provisions of Directive 2014/53/EU,2011/65/EU. A copy of the Declaration of conformity can be found at https://www.tuya.com.

This product must not be disposed of as normal household waste, in accordance with the EU directive for waste electrical and electronic equipment (WEEE-2012/19/EU). Instead, it should be disposed of by returning it to the point of sale, or to a municipal recycling collection point.

The device could be used with a separation distance of 20cm to the human body.